EasyFiber Baffle modular acoustic baffle

EasyFiber Baffle modular acoustic baffle

EasyFiber line of modular sound-absorbing panels is characterized by its modern design thanks to the contrast between the internal “black core” and the wide choice of colors of high-quality pure virgin wool fabrics, with sound-transparent and fireproof properties.

EasyFiber Baffle acoustic baffle is proposed with a double-sided coating and has been specially designed for suspended ceiling installations, in the acoustic baffle type position. From the point of view of acoustic correction, the positioning of the sound-absorbing panels vertically, in the acoustic baffle mode, improves the performance of the panel compared to the classic positioning adhering to the ceiling or wall for various reasons:

- according to physics, a porous material separated from its support (wall or ceiling) by at least 10 cm improves its sound-absorbing power by about 15% compared to installation in adherence.

- For the wave breaking effect or breaking of the incident wave, where the panel in the acoustic baffle position is more of an obstacle to the rebound of the acoustic waves between the parallel vertical walls, thus significantly improving the acoustic diffraction effect of the panels.

- It improves the distribution of panels within spaces with large volumes, allowing installation not only perimeter on the wall, but also for parallel rows within the space.

EasyFiber Baffle acoustic baffle is available in a large variety of formats: rectangular, square, round, triangular, hexagonal or wave, which allow the creation of geometric compositions with an impactful design.

Furthermore, the sound absorbing panels of the EasyFiber line are available in various versions:

- with double-sided covering, for baffle-type suspended ceiling installation;

- with single-sided covering, for ceiling or wall installation, adherent or suspended, for more information and photos click here;

- without covering, for acoustic treatments and low budget projects, for more information and photos click here.

Less is more!

The manufacturing process of the EasyFiber Baffles acoustic baffles is simple and at the same time innovative: it involves thermal lamination of the polyester, hot gluing of the fabric and finally the shaping phase through specific cuts to the chosen formats. In order to significantly increase the sound absorption performance of the materials used, we perform thermo-polishing operations on the internal sound-absorbing material. This Multidensity treatment gives the baffles the necessary structural rigidity and allows the elimination of any rigid support, both internal and in the perimeter of the panel, as well as any additional weight and improves the performance from the acoustic point of view as it adds the multidensity component to the polyester fiber.

The EasyFiber Baffle acoustic baffle offers the best sound absorption performance for this product category, it is classified in class “A” of sound absorption according to the reference standards: ISO 354: 2003 and ISO 11654: 1998.

Ease of installation

Ceiling installation in vertical position, in acoustic baffle mode using the suspension mounting kit with nylon cables. The EasyFiber baffle panels are ultra-light and safe, entirely made of fireproof materials.

Finishes

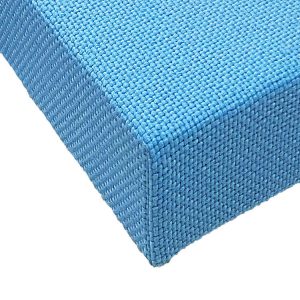

We have a wide choice of 60 colors of made in Italy fabrics, in pure 100% virgin wool or in a mix of 75% wool and 25% polyamide (fireproof class 1 IM).

The covering in Trevira CS® fabric, 100% polyester (class 1 – B-s1, d0) is available.

Internal material available in black, white and grey.

Formats and standard sizes

600 x 600 mm; 700 x 700 mm; 800 x 800 mm; 300 x 1200 mm; 400 x 1200 mm; 600 x 1200 mm; 400/240 x 1200 mm; diameter 700 mm; hexagon side 350 mm/570 mm; triangle side 800 mm.

Thickness 40 mm (tolerance +/- 2 mm).

Technical Characteristics

Internal coatings

100% pure virgin wool fabric – 75% wool and 25% polyamide fabric – 100% polyester Trevira CS® fabric.

Abrasion resistance:> 50,000 Martindale cycles (± 20%)

Light resistance: EN ISO 105-B02-5

Friction resistance: EN ISO 105-X12 – Wet 4/5 – Sec 5

Flammability: 1 IM UNI 9175 – EN 1021-1: 2006 – EN 1021-2: 2006 – TB 117: 2013 – IMO

Treatments: hydro-oil repellent.

Internal sound-absorbing material

100% polyester fiber (PET), average density 45 kg / m3, Multidensity thermolysis treatment. Available in black, white and grey.

General characteristics: Resistant to chemical agents (acids, salts, hydrocarbons), fungi, bacteria and microorganisms, water-repellent, non-rotting, odorless. Not dangerous substance according to D.M. 02/12/93.

Flammability: UNI EN 13501-1: 2009 B-s2, d0 – It does not emit opaque or toxic fumes (ANFOR F1 16-101).

Sound absorption class “A” according to UNI EN ISO 354: 2003 (highly sound absorbing).